Introduction to Wood Staining with Food Coloring

Staining wood with food coloring – The allure of transforming ordinary wood into vibrant, uniquely hued pieces, using nothing more than readily available food coloring, is undeniably captivating. It’s a technique that whispers of simplicity, affordability, and a touch of playful experimentation, perfect for both seasoned woodworkers and enthusiastic beginners. The subtle, often unexpected results offer a compelling alternative to the more predictable outcomes of traditional wood stains.This method, however, presents a different approach to wood finishing than the established techniques using commercial wood stains.

While traditional stains penetrate deeply, offering rich, long-lasting color, food coloring offers a more delicate, surface-level tint. This difference impacts both the final appearance and the longevity of the finish. The subtle nuances of color and the relative ease of the process make food coloring an appealing option for smaller projects or when a less intense, more natural-looking finish is desired.

Ever tried staining wood with food coloring? It’s a surprisingly easy and affordable way to add a pop of color to your DIY projects! The process is similar to dyeing Easter eggs, in fact, you can even use the same food coloring you’d find for decorating eggs, like those you might find described on this helpful site: food coloring for easter eggs.

Just remember to seal your wood project afterwards for a longer-lasting finish, unlike your Easter eggs which are meant to be eaten (hopefully!). So, get creative and experiment with different shades for unique wooden creations!

Conversely, the lack of deep penetration means the color may fade more readily with exposure to sunlight or wear, and the finish might require more frequent maintenance.

Suitable Wood Types for Food Coloring Staining

The success of food coloring staining hinges significantly on the type of wood used. The grain structure and porosity of the wood directly influence how well the color is absorbed and retained. Woods with tighter grains and lower porosity generally yield more subtle and even color results, while more porous woods can create a more dramatic, possibly uneven finish, depending on the desired effect.

Understanding these characteristics is crucial for achieving the desired outcome.

| Wood Type | Grain | Porosity | Suitability for Food Coloring |

|---|---|---|---|

| Basswood | Fine, even | Low | Excellent; accepts color evenly, ideal for beginners. |

| Birch | Fine to medium, even | Medium | Good; produces a consistent, subtle color. |

| Pine | Coarse, visible knots | High | Moderate; color absorption varies, resulting in a more rustic look. Requires careful application for even results. |

| Maple | Fine, even | Medium-low | Good; produces a clear, even color, especially with a pre-sealer. |

Achieving Specific Colors and Effects

The magic of food coloring lies not just in its vibrant hues, but in its versatility. By understanding the principles of color mixing and employing a few clever techniques, you can transform ordinary wood into extraordinary pieces, each imbued with a unique personality. The possibilities are as boundless as your imagination.Mixing food coloring to achieve specific shades and tones is akin to painting with a palette of natural pigments.

The key is to start with small amounts and gradually build up the desired intensity. Remember that the wood itself will influence the final color; lighter woods will show the colors more vividly than darker ones. Experimentation is crucial; don’t be afraid to try different combinations.

Color Mixing Techniques

Creating a specific shade requires a methodical approach. For instance, to achieve a deep mahogany, you might start with a base of red food coloring, then add a touch of brown to deepen the hue and a hint of yellow to warm it. For a softer, more muted tone, dilute the mixture with water. Conversely, for a more intense color, use a higher concentration of food coloring.

Keep in mind that the final color will be affected by the type of wood and the number of coats applied. Testing on scrap wood before applying to your project is always recommended. Precise measurements aren’t essential; trust your eye and adjust as needed.

Creating Unique Patterns and Designs, Staining wood with food coloring

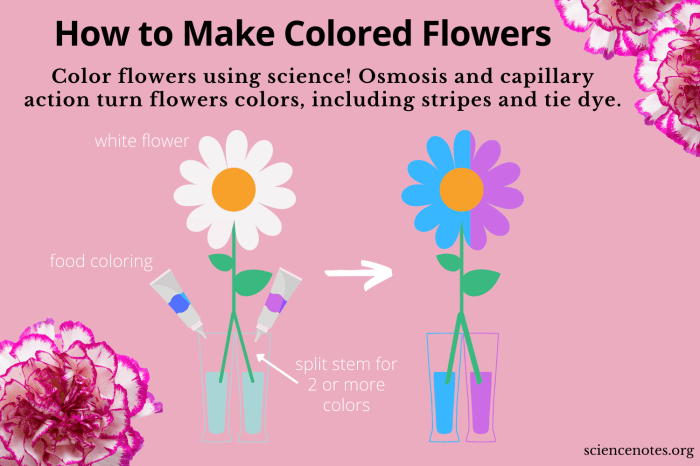

The beauty of this technique lies in its ability to create unique patterns. One method involves applying multiple colors in layers, allowing each layer to dry slightly before applying the next. This creates a depth and complexity not achievable with single-color stains. Another technique is to use masking tape to create geometric designs, applying different colors within the taped areas.

Removing the tape reveals sharp lines and contrasting colors. Freehand application with a sponge or brush can produce a more organic, less structured effect. Think of the possibilities: stripes, marbling, ombré – the only limit is your creativity.

Creating a Rustic Distressed Look

This step-by-step guide will demonstrate how to achieve a rustic, distressed look on a wood surface using food coloring. This effect mimics the aged appearance of antique furniture, adding character and charm.

- Preparation: Sand the wood surface to remove any imperfections and ensure a smooth finish. Clean the surface thoroughly with a damp cloth to remove dust and debris.

- Base Coat: Apply a base coat of a diluted mixture of brown and black food coloring. This creates a foundation for the distressing effect. Allow it to dry completely.

- Distressing: Once dry, use sandpaper (medium grit) to lightly sand away parts of the base coat, revealing the natural wood color underneath. Focus on the edges and corners to create a more authentically worn look. Avoid sanding too aggressively, as you want to maintain some of the base color.

- Highlighting: Apply a diluted mixture of a lighter color, such as a beige or light brown, to certain areas to highlight the distressed effect. Focus on raised areas or edges to create depth and contrast.

- Sealing (Optional): Apply a clear sealant to protect the finished surface and enhance its durability. Allow it to dry completely before handling.

Sealing and Finishing the Stained Wood: Staining Wood With Food Coloring

The vibrant hues achieved through food coloring deserve a protective finish, not only to enhance their longevity but also to deepen their richness and bring out the wood’s natural grain. Choosing the right sealant and applying it correctly is crucial; a poorly executed finish can dull the colors and leave your project looking amateurish. The process, however, is surprisingly straightforward, demanding patience more than expertise.The selection of a sealant depends largely on the desired level of protection and the overall aesthetic.

Different sealants offer varying degrees of durability, water resistance, and sheen. Applying the finish correctly is as important as choosing the right product. Careful attention to detail will ensure a professional-looking result that showcases the beauty of your food-colored wood.

Suitable Sealants for Food Coloring Stained Wood

Several sealants work well with food-colored wood, each possessing unique properties. Water-based polyurethane offers excellent protection and a clear, slightly glossy finish, allowing the vibrant colors to shine through. It’s relatively easy to apply and clean up, making it a popular choice for beginners. A more durable option is oil-based polyurethane, which provides superior water resistance and a harder, more scratch-resistant surface.

However, it requires mineral spirits for cleanup and takes longer to dry. Finally, wax offers a softer, more natural finish, enhancing the wood’s texture while providing some protection. It’s ideal for pieces that require a less-glossy, more rustic look. Each sealant will affect the final appearance differently; the choice depends on the intended use and desired aesthetic.

For example, a water-based polyurethane might be suitable for a decorative box, while an oil-based polyurethane would be better for a kitchen cutting board.

Finishing Techniques: Varnish, Polyurethane, and Wax

Applying varnish, polyurethane, or wax involves distinct techniques, each impacting the final look and feel. Varnish, traditionally made from natural resins, provides a hard, glossy finish that protects against scratches and moisture. It often requires multiple thin coats, allowing each layer to dry completely before applying the next. Polyurethane, available in both water-based and oil-based formulas, offers superior durability and water resistance compared to varnish.

It is applied similarly, with thin coats and adequate drying time between applications. Wax, a softer option, provides a subtle sheen and enhances the wood’s natural texture. It’s applied with a cloth, rubbed in gently, and then buffed to a smooth finish. The choice of finish directly influences the final appearance of the stained wood; for instance, a glossy polyurethane will showcase the colors differently than a matte wax finish.

Sealing and Finishing Process

Before applying any sealant, ensure the wood is completely dry. This is crucial to prevent trapping moisture, which can lead to warping or peeling. For water-based polyurethane, apply thin, even coats using a brush or rag, allowing each coat to dry completely according to the manufacturer’s instructions – typically 2-4 hours between coats. Sand lightly with fine-grit sandpaper between coats to create a smooth surface.

For oil-based polyurethane, follow the same procedure, but remember to clean your brushes with mineral spirits. Wax application involves rubbing a small amount onto the wood’s surface with a soft cloth, working it into the grain. Buff the surface with a clean cloth to achieve a smooth, even finish. The drying time for wax is relatively short, but it’s advisable to let it cure for a few hours before handling the finished piece.

Proper drying time between coats is paramount for a durable and attractive finish; neglecting this step can lead to an uneven or weak finish. Imagine applying a second coat of polyurethane before the first is completely dry – the result would likely be a sticky, uneven mess.

Safety Precautions and Considerations

Working with wood and food coloring, while seemingly innocuous, requires careful attention to safety. The seemingly harmless nature of the materials can lead to unforeseen hazards if proper precautions aren’t taken. This section details essential safety measures to ensure a safe and enjoyable woodworking experience. Remember, safety is paramount, even in seemingly simple projects.

Potential health risks associated with food coloring and wood stains, while generally low, exist. Certain food colorings may contain ingredients that can cause allergic reactions in sensitive individuals. Wood dust, regardless of the type of wood, can be a respiratory irritant. The combination of these materials necessitates a proactive approach to safety.

Necessary Safety Equipment and Disposal

Appropriate safety equipment minimizes risks and protects your health. The following table Artikels essential equipment, their purpose, necessary precautions, and proper disposal methods.

| Equipment | Purpose | Safety Precautions | Disposal Method |

|---|---|---|---|

| Gloves (nitrile or similar) | Protect hands from stains and potential irritants. | Ensure gloves are undamaged before use. Replace immediately if torn or punctured. | Dispose of gloves in a lined trash receptacle after use. |

| Eye Protection (safety glasses) | Shield eyes from splashes of food coloring or wood stain. | Ensure glasses fit snugly and provide adequate coverage. | Clean glasses thoroughly with soap and water after each use. |

| Dust Mask (respirator for fine dust) | Prevent inhalation of wood dust, a known respiratory irritant. | Choose a mask with appropriate filtration level (N95 or higher recommended for fine wood dust). Ensure a proper seal around the face. | Follow manufacturer’s instructions for cleaning or disposal. |

| Apron or protective clothing | Protect clothing from stains and spills. | Choose a durable apron made of a stain-resistant material. | Launder soiled clothing separately. |

| Well-ventilated workspace | Dissipates wood dust and fumes. | Work outdoors or in a space with adequate ventilation, such as a workshop with exhaust fans. | N/A |

Mitigating Health Risks

Several strategies effectively mitigate potential health risks. These steps minimize exposure to irritants and allergens, ensuring a safer woodworking process.

Always perform the staining process in a well-ventilated area to reduce the inhalation of wood dust and food coloring fumes. Wearing appropriate personal protective equipment (PPE) such as gloves, eye protection, and a respirator is crucial. Thoroughly wash your hands after handling food coloring and wood. If skin irritation occurs, discontinue use and consult a medical professional.

For those with known allergies, carefully review the ingredients of the food coloring before use. Consider using hypoallergenic alternatives if necessary. Proper disposal of waste materials, including used gloves and cleaning rags, prevents accidental exposure and environmental contamination.

Questions and Answers

Is food coloring toxic?

Food coloring intended for consumption is generally considered non-toxic, but it’s crucial to avoid contact with eyes and mouth. Always work in a well-ventilated area.

How long does food coloring stain last?

The longevity depends on the type of wood, the sealant used, and the level of exposure to sunlight and moisture. Proper sealing significantly extends its lifespan.

Can I use any type of wood?

Softwoods like pine and basswood are generally easier to stain than hardwoods. Hardwoods may require more preparation and multiple coats.

How do I clean up food coloring spills?

Clean spills immediately with warm soapy water. For stubborn stains, try a mild bleach solution.